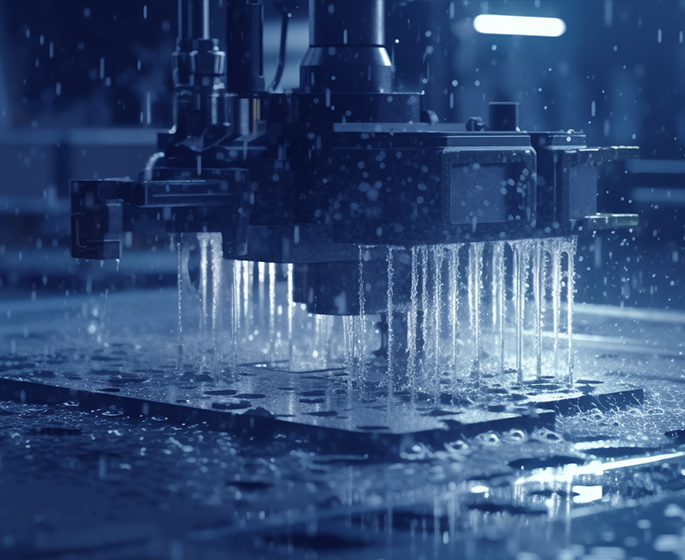

We are the first company that implemented the application of UHP Hydroblasting in the undustry of ship repairing in China, and we are the technical specification framer of water jet for commercial vessels and warships. We are the first Chinese company to provide a comprehensive UHP Hydroblasting solution. Our TCX and TCD adopted unique structure design, in which many parts are customized, and have applied for patent with a number of intellectual property rights. At the same time, we have optimized details in process and manufacturing for several times to ensure the quality of each product is consistent, and achieve the cost advantage and quality control of small batch production. We fully implement ESG principles in our production process, and our customers use our products to ensure that their companies meet ESG standards

We emphasize environmental protection and sustainability by fully implementing ESG principles in our production processes. This commitment ensures our products help customers meet their ESG standards. Through repeated optimization of manufacturing processes, we ensure consistent product quality while achieving cost efficiency and quality control in small batch production. Our eco-friendly practices underscore our dedication to a greener future.