Proper surface preparation is crucial in the marine and shipbuilding industry, as many coating failures result from inadequate cleaning. Ensuring a clean and well-prepared hull surface is essential for the coating's durability and effective corrosion protection in ship construction, ship maintenance, and ship repair.

| Items | Abrasive Blasting | Manual hydroblasting | Wall-climbing robot | Treatment Carrier |

|---|---|---|---|---|

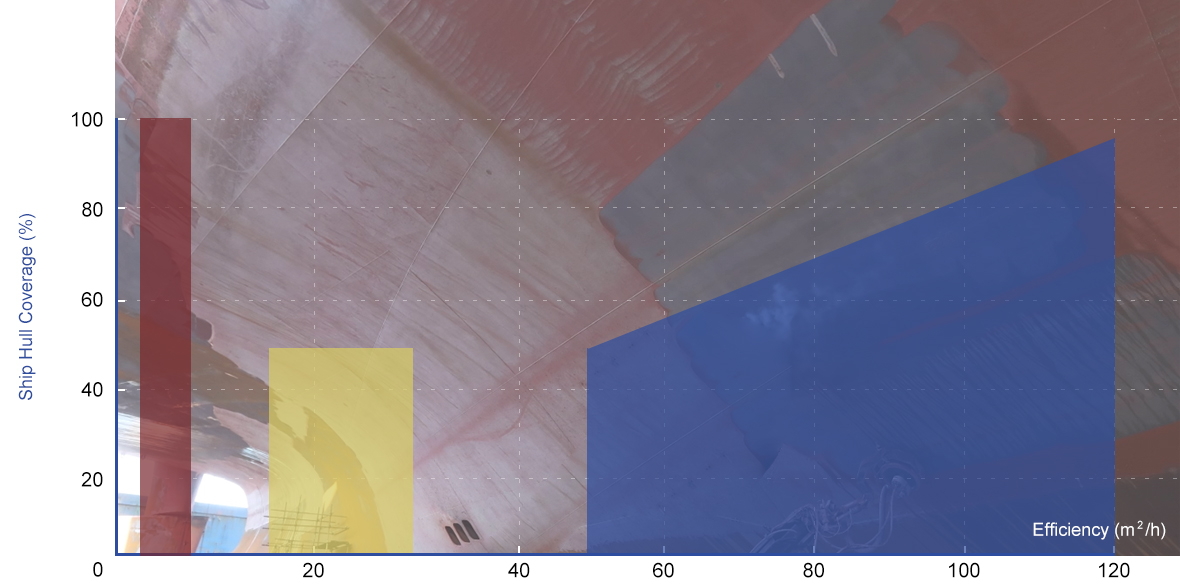

| Efficiency | 6 - 8 ㎡ /h | 6 - 8 ㎡ /h | 15 - 30 ㎡ /h | up to 50/120 ㎡/h |

| Required Equipment |

Scaffold, abrasive materials, blasting pot,

air compressor, and containment system, etc. |

Scaffold, high-pressure water jet systems,

hoses, UHP pump, protective gear, etc. |

Robot unit, UHP pump, electronic cabinet,

long electronic wires, fall arresters, and safety harnesses, etc. |

All-in-one system with built-in electronic

and recovery modules |

| Required Labor |

High labor demand for setup, operation, and

maintenance |

Very high labor demand for manual operation

and safety oversight |

Moderate labor demand for setup and

monitoring |

Low labor demand due to automation and remote

operation capabilities |

| Working Coverage |

100% | 100% | 45% | 95% |

| Cleaning Effect |

Manual cleaning cannot reach the request

result one time, needs to be cleaned several times, and prepared surface is less

consistent |

Manual cleaning cannot reach the request result one time, needs to be cleaned several times, and prepared surface is less consistent | Effective in accessible areas but may

struggle with complex geometries |

Consistently high cleaning quality, meeting

near-white metal standards (WJ-2 / Wa 2½) |

| Risk Points | High risk of dust and particulate exposure, potential for equipment-related injuries | High risk of respiratory issues, physical strain, and accidents | Potential for mechanical failure and falling risk due to excessive water pressure and the magnet's adsorption ability weakness | Minimal |

| Environmental Impact | Extremely air pollution | Contaminate local water bodies and requires large volumes of water and energy, potentially impacting marine ecosystems and local resources, and proper waste management is crucial to mitigate these environmental risks | Recycling and sewage treatment facilities must be equipped | Dust-free, water-saving and environmentally friendly with 99% wastewater recovery |

Manual Blasting

Magnetic Hull Crawler

D10

X25